Tappi Charts

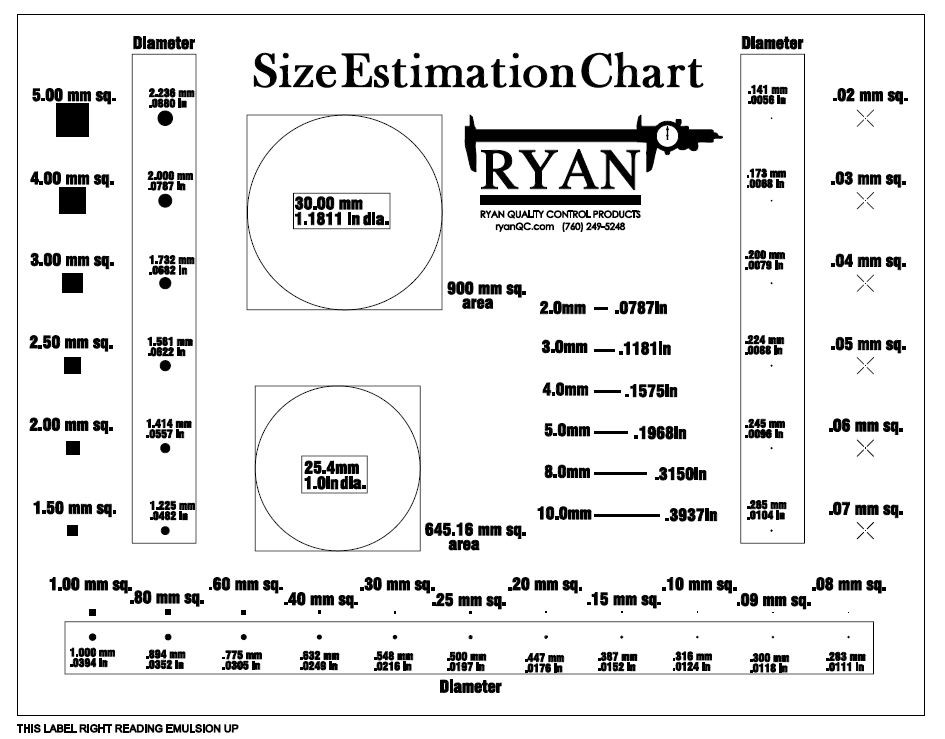

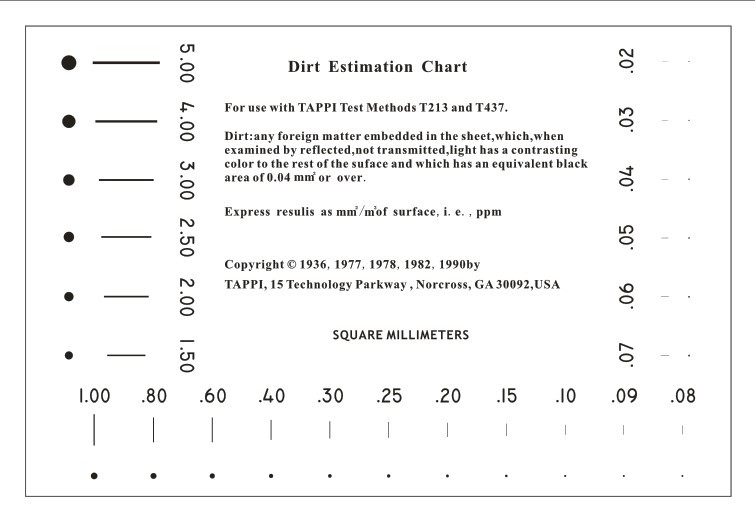

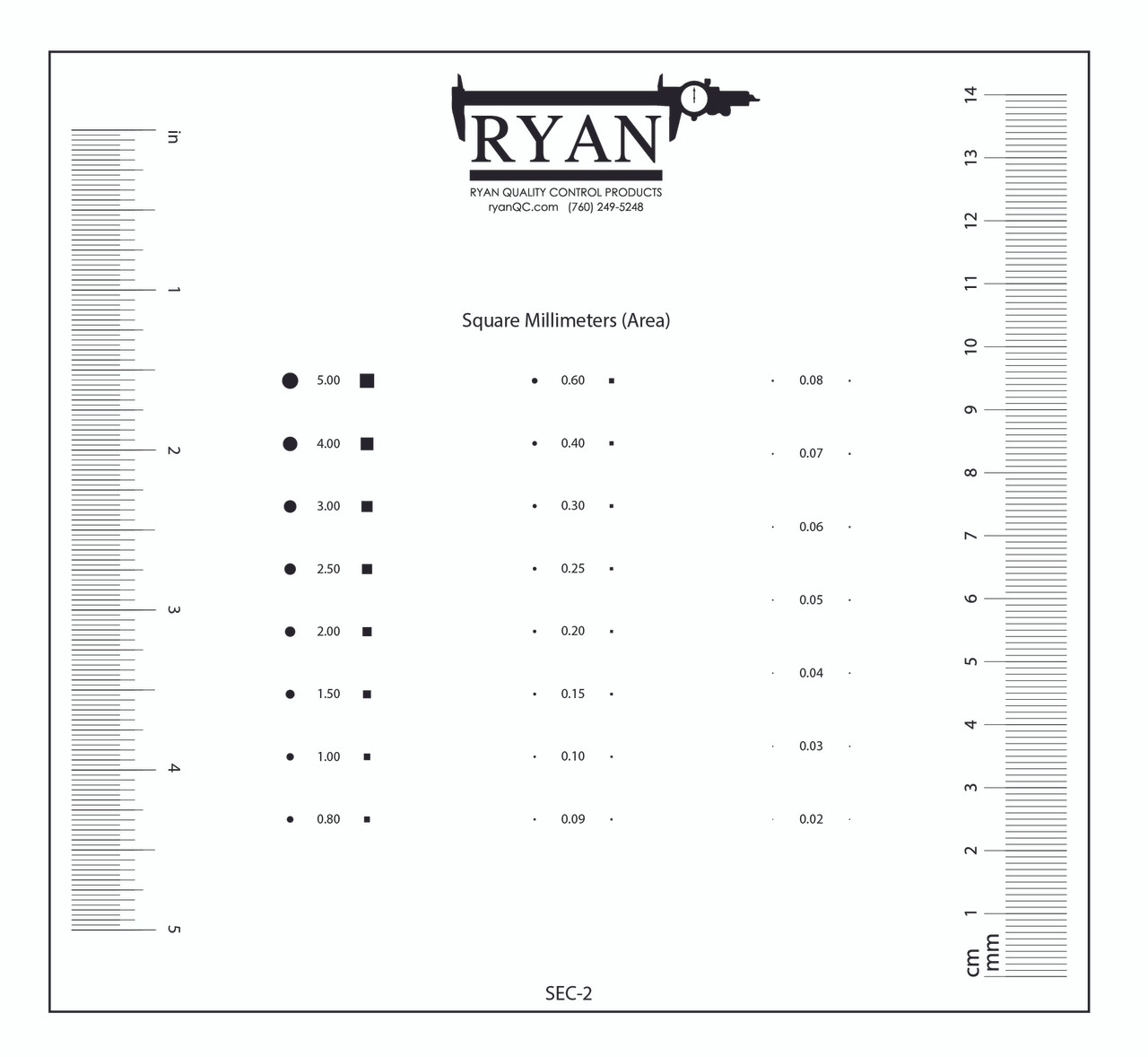

Tappi Charts - Tappi charts were developed to work in conjunction with technical standards developed for the detection of defects in paper and pulp and are now widely used as visual inspection tools by. The chart can be used in a large number of applications where there is a need to estimate a size (area) by way of a direct comparison to a known circular area. Measure the size of defects in. The tappi dirt estimation chart is an opaque chart used to estimate the equivalent black area (eba) of dirt or other colored specks over the range of 0.02 to 5.00 square millimeters. This document describes a transparent chart method for estimating the size of defects or inclusions between 0.02 and 5.00 mm2. Also known as the tappi dirt estimation chart, it contains a list of different. Tappi’s visual detection charts help you pinpoint flaws such as particulates, embedded defects, or inclusions with confidence. The template is the same as the size estimation and calibrate size. Tappi’s visual detection charts help you pinpoint flaws such as particulates, embedded defects, or inclusions with confidence. The transparent chart developed for this method may be used to estimate the size (area) of spots, defects, and/or other inclusions over the range of 0.02 to 5.00 mm2. Purchase your estimation charts today! Tappi’s visual detection charts help you pinpoint flaws such as particulates, embedded defects, or inclusions with confidence. This is the only chart that can properly be used in reflected light tests to determine eba (equivalent black area). Purchase your estimation charts today! This document describes a transparent chart method for estimating the size of defects or inclusions between 0.02 and 5.00 mm2. The chart contains a series of round and rectangular. The tappi dirt estimation chart is an opaque chart used to estimate the equivalent black area (eba) of dirt or other colored specks over the range of 0.02 to 5.00 square millimeters. Using a tappi chart is essential for examining the size and dimensions of microscopic spots. The template is the same as the size estimation and calibrate size. Also known as the tappi dirt estimation chart, it contains a list of different. The template is the same as the size estimation and calibrate size. Tappi’s visual detection charts help you pinpoint flaws such as particulates, embedded defects, or inclusions with confidence. Purchase your estimation charts today! This is the only chart that can properly be used in reflected light tests to determine eba (equivalent black area). This document describes a transparent chart. The chart contains a series of round and rectangular. The transparent chart developed for this method may be used to estimate the size (area) of spots, defects, and/or other inclusions over the range of 0.02 to 5.00 mm2. The transparent chart developed for this method may be used to estimate the size (area) of spots, defects, and/or other inclusions over. The transparent chart developed for this method may be used to estimate the size (area) of spots, defects, and/or other inclusions over the range of 0.02 to 5.00 mm2. This is the only chart that can properly be used in reflected light tests to determine eba (equivalent black area). Measure the size of defects in. The chart can be used. Purchase your estimation charts today! Tappi’s visual detection charts help you pinpoint flaws such as particulates, embedded defects, or inclusions with confidence. The transparent chart developed for this method may be used to estimate the size (area) of spots, defects, and/or other inclusions over the range of 0.02 to 5.00 mm2. Measure the size of defects in. This document describes. Tappi’s visual detection charts help you pinpoint flaws such as particulates, embedded defects, or inclusions with confidence. The chart contains a series of round and rectangular. The transparent chart developed for this method may be used to estimate the size (area) of spots, defects, and/or other inclusions over the range of 0.02 to 5.00 mm2. Tappi charts were developed to. Purchase your estimation charts today! The transparent chart developed for this method may be used to estimate the size (area) of spots, defects, and/or other inclusions over the range of 0.02 to 5.00 mm2. Using a tappi chart is essential for examining the size and dimensions of microscopic spots. Tappi’s visual detection charts help you pinpoint flaws such as particulates,. This document describes a transparent chart method for estimating the size of defects or inclusions between 0.02 and 5.00 mm2. The chart contains a series of round and rectangular. The transparent chart developed for this method may be used to estimate the size (area) of spots, defects, and/or other inclusions over the range of 0.02 to 5.00 mm2. Measure the. This document describes a transparent chart method for estimating the size of defects or inclusions between 0.02 and 5.00 mm2. This is the only chart that can properly be used in reflected light tests to determine eba (equivalent black area). Purchase your estimation charts today! Measure the size of defects in. Tappi charts were developed to work in conjunction with. Tappi’s visual detection charts help you pinpoint flaws such as particulates, embedded defects, or inclusions with confidence. This is the only chart that can properly be used in reflected light tests to determine eba (equivalent black area). Also known as the tappi dirt estimation chart, it contains a list of different. Measure the size of defects in. The transparent chart. The chart contains a series of round and rectangular. The template is the same as the size estimation and calibrate size. Measure the size of defects in. Purchase your estimation charts today! This is the only chart that can properly be used in reflected light tests to determine eba (equivalent black area). Measure the size of defects in. Tappi charts were developed to work in conjunction with technical standards developed for the detection of defects in paper and pulp and are now widely used as visual inspection tools by. This is the only chart that can properly be used in reflected light tests to determine eba (equivalent black area). The transparent chart developed for this method may be used to estimate the size (area) of spots, defects, and/or other inclusions over the range of 0.02 to 5.00 mm2. Purchase your estimation charts today! This document describes a transparent chart method for estimating the size of defects or inclusions between 0.02 and 5.00 mm2. The template is the same as the size estimation and calibrate size. The chart contains a series of round and rectangular. Tappi’s visual detection charts help you pinpoint flaws such as particulates, embedded defects, or inclusions with confidence. The chart can be used in a large number of applications where there is a need to estimate a size (area) by way of a direct comparison to a known circular area. The transparent chart developed for this method may be used to estimate the size (area) of spots, defects, and/or other inclusions over the range of 0.02 to 5.00 mm2. The tappi dirt estimation chart is an opaque chart used to estimate the equivalent black area (eba) of dirt or other colored specks over the range of 0.02 to 5.00 square millimeters.Inspection Charts

CITEC 0109DIRTT Size Estimation Tappi Chart available online Caulfield Industrial

TAPPI ROLL NUMBERING SYSTEM

TAPPI Manufacture and Process Control of TAPPI Size Estimation Charts PDF Exposure

TAPPI Brightness of sample5 sheets under alkaline conditions Download Scientific Diagram

Size Estimation Transparency Chart Ryan Quality Control

美國TAPPI標準T213高精度點規 黑點表 線規 污點規 菲林尺 污點數卡

SEC2 Size Estimation Transparency Chart and Ruler Measures Square mm Area Ryan Quality Control

ISO and TAPPI Measurement Standards for Commonly Used Optical Properties * Download Table

Tappi Versus Iso Brightness Scale

Also Known As The Tappi Dirt Estimation Chart, It Contains A List Of Different.

Using A Tappi Chart Is Essential For Examining The Size And Dimensions Of Microscopic Spots.

Purchase Your Estimation Charts Today!

Tappi’s Visual Detection Charts Help You Pinpoint Flaws Such As Particulates, Embedded Defects, Or Inclusions With Confidence.

Related Post: