Metric Tolerance Chart

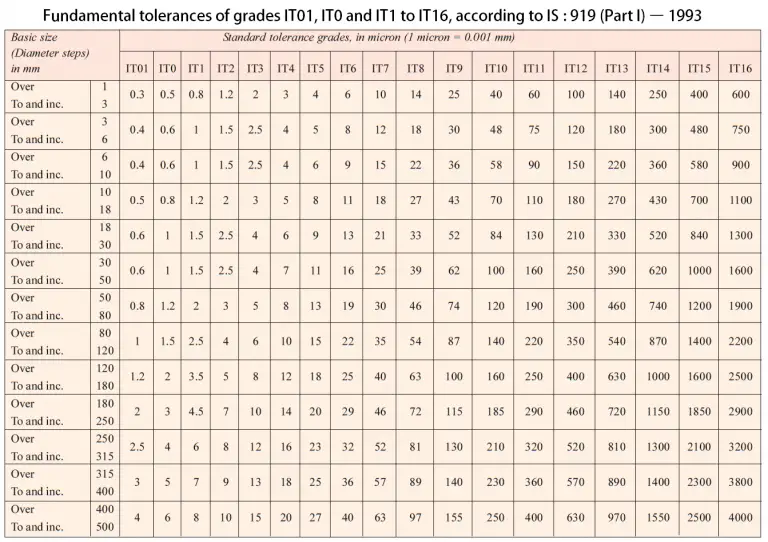

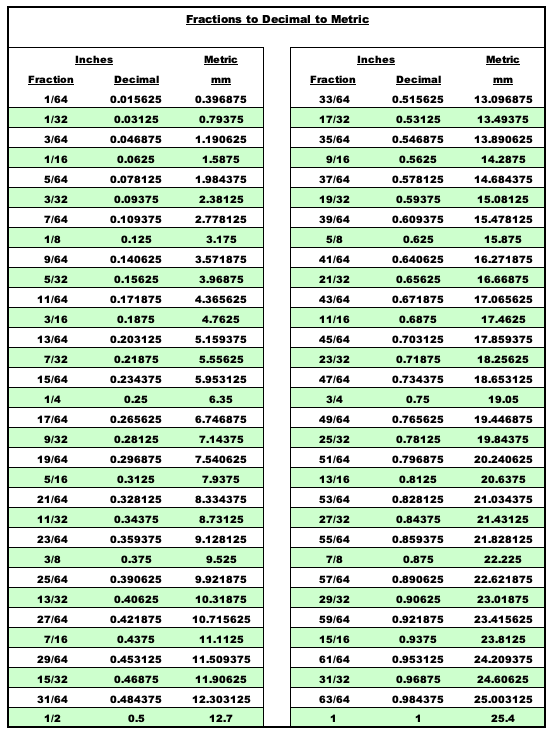

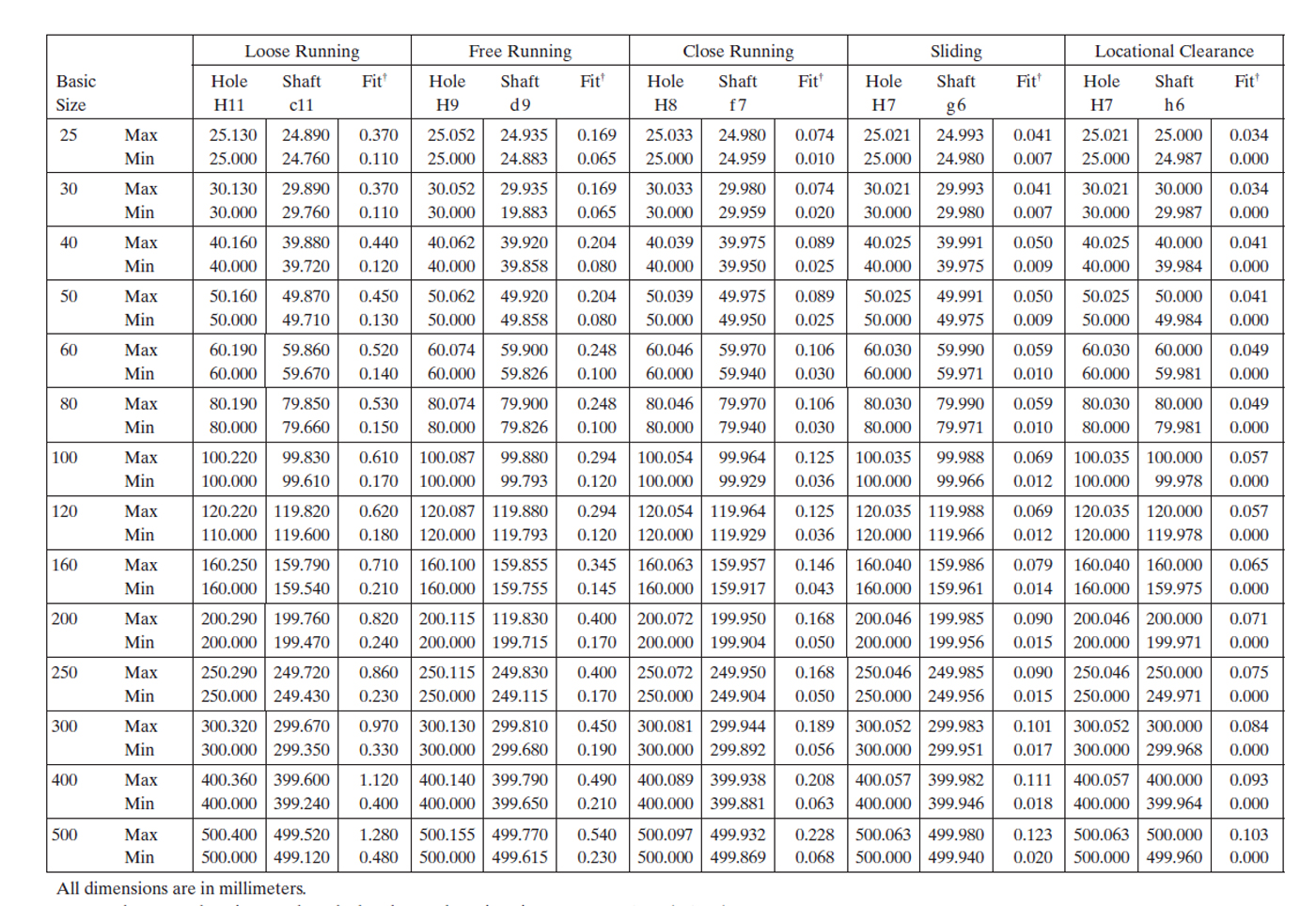

Metric Tolerance Chart - Calculate metric shaft tolerances with our iso 286 chart calculator, providing precise values for shaft and hole tolerances according to international standards, ensuring accurate engineering. The following engineering calculator will show the plus and minus tolerance for the specific iso 286 shaft tolerance data. Loose running fit for wide commercial tolerances or allowances on external members. The first provides the charts for the fundamental deviations (g, j, etc.) and tolerance grades (7, 8, 9, etc.), out of which the limits of the tolerance classes (h7, g6, etc.) can be calculated. Enter your desired preferred tolerance grade and the nomial size. Nominal size in mm, upper and lower tolerance shown in microns (.001mm) The fit for precision round bar is defined numerically, ranging from h5 to h12 in the metric tolerance chart below. Evaluate any tolerance quickly and easily Use this chart to determine what the round bar tolerance is in. All tolerances classes and sizes according to standard. Free iso metric tolerance zone calculator. The following engineering calculator will show the plus and minus tolerance for the specific iso 286 shaft tolerance data. The first provides the charts for the fundamental deviations (g, j, etc.) and tolerance grades (7, 8, 9, etc.), out of which the limits of the tolerance classes (h7, g6, etc.) can be calculated. Loose running fit for wide commercial tolerances or allowances on external members. Enter your desired preferred tolerance grade and the nomial size. Free running fit not for. All tolerances classes and sizes according to standard. Nominal size in mm, upper and lower tolerance shown in microns (.001mm) The fit for precision round bar is defined numerically, ranging from h5 to h12 in the metric tolerance chart below. Evaluate any tolerance quickly and easily The following engineering calculator will show the plus and minus tolerance for the specific iso 286 shaft tolerance data. Free iso metric tolerance zone calculator. The following defines the preferred tolerance basis for hole and shaft per. Evaluate any tolerance quickly and easily Use this chart to determine what the round bar tolerance is in. Use this chart to determine what the round bar tolerance is in. All tolerances classes and sizes according to standard. Enter your desired preferred tolerance grade and the nomial size. The first provides the charts for the fundamental deviations (g, j, etc.) and tolerance grades (7, 8, 9, etc.), out of which the limits of the tolerance classes (h7, g6,. Enter your desired preferred tolerance grade and the nomial size. The fit for precision round bar is defined numerically, ranging from h5 to h12 in the metric tolerance chart below. The first provides the charts for the fundamental deviations (g, j, etc.) and tolerance grades (7, 8, 9, etc.), out of which the limits of the tolerance classes (h7, g6,. Free running fit not for. The fit for precision round bar is defined numerically, ranging from h5 to h12 in the metric tolerance chart below. Use this chart to determine what the round bar tolerance is in. Nominal size in mm, upper and lower tolerance shown in microns (.001mm) The following defines the preferred tolerance basis for hole and shaft. The first provides the charts for the fundamental deviations (g, j, etc.) and tolerance grades (7, 8, 9, etc.), out of which the limits of the tolerance classes (h7, g6, etc.) can be calculated. Loose running fit for wide commercial tolerances or allowances on external members. The following defines the preferred tolerance basis for hole and shaft per. Nominal size. Calculate metric shaft tolerances with our iso 286 chart calculator, providing precise values for shaft and hole tolerances according to international standards, ensuring accurate engineering. The first provides the charts for the fundamental deviations (g, j, etc.) and tolerance grades (7, 8, 9, etc.), out of which the limits of the tolerance classes (h7, g6, etc.) can be calculated. Loose. The following engineering calculator will show the plus and minus tolerance for the specific iso 286 shaft tolerance data. Free iso metric tolerance zone calculator. Nominal size in mm, upper and lower tolerance shown in microns (.001mm) Free running fit not for. Enter your desired preferred tolerance grade and the nomial size. The following engineering calculator will show the plus and minus tolerance for the specific iso 286 shaft tolerance data. Use this chart to determine what the round bar tolerance is in. The following defines the preferred tolerance basis for hole and shaft per. Evaluate any tolerance quickly and easily Free running fit not for. The first provides the charts for the fundamental deviations (g, j, etc.) and tolerance grades (7, 8, 9, etc.), out of which the limits of the tolerance classes (h7, g6, etc.) can be calculated. The following defines the preferred tolerance basis for hole and shaft per. Loose running fit for wide commercial tolerances or allowances on external members. Free iso. Free running fit not for. The first provides the charts for the fundamental deviations (g, j, etc.) and tolerance grades (7, 8, 9, etc.), out of which the limits of the tolerance classes (h7, g6, etc.) can be calculated. Evaluate any tolerance quickly and easily Nominal size in mm, upper and lower tolerance shown in microns (.001mm) Calculate metric shaft. Enter your desired preferred tolerance grade and the nomial size. The following defines the preferred tolerance basis for hole and shaft per. All tolerances classes and sizes according to standard. Free running fit not for. The fit for precision round bar is defined numerically, ranging from h5 to h12 in the metric tolerance chart below. Nominal size in mm, upper and lower tolerance shown in microns (.001mm) The following engineering calculator will show the plus and minus tolerance for the specific iso 286 shaft tolerance data. Free iso metric tolerance zone calculator. Loose running fit for wide commercial tolerances or allowances on external members. Use this chart to determine what the round bar tolerance is in.Tolerance Chart Table Of Metric Shaft Tolerances Per vrogue.co

Metric Tolerance Chart PDF PDF Engineering Tolerance Scientific Observation

Metric Tolerance Chart

Basic tolerances and tolerance fields Bossard Group

Avoiding the Risks of Standard to Metric Tolerance Chart Conversion Metal Cutting Corporation

ISO Tolerances For Holes PDF Engineering Tolerance World Economy

Metric Tolerance Chart for ISO 2862 Round Bar Tolerances

Metric Tolerance Chart

Tolerances Iso

Request Rejected

Calculate Metric Shaft Tolerances With Our Iso 286 Chart Calculator, Providing Precise Values For Shaft And Hole Tolerances According To International Standards, Ensuring Accurate Engineering.

Evaluate Any Tolerance Quickly And Easily

The First Provides The Charts For The Fundamental Deviations (G, J, Etc.) And Tolerance Grades (7, 8, 9, Etc.), Out Of Which The Limits Of The Tolerance Classes (H7, G6, Etc.) Can Be Calculated.

Related Post: