Keensert Drill Chart

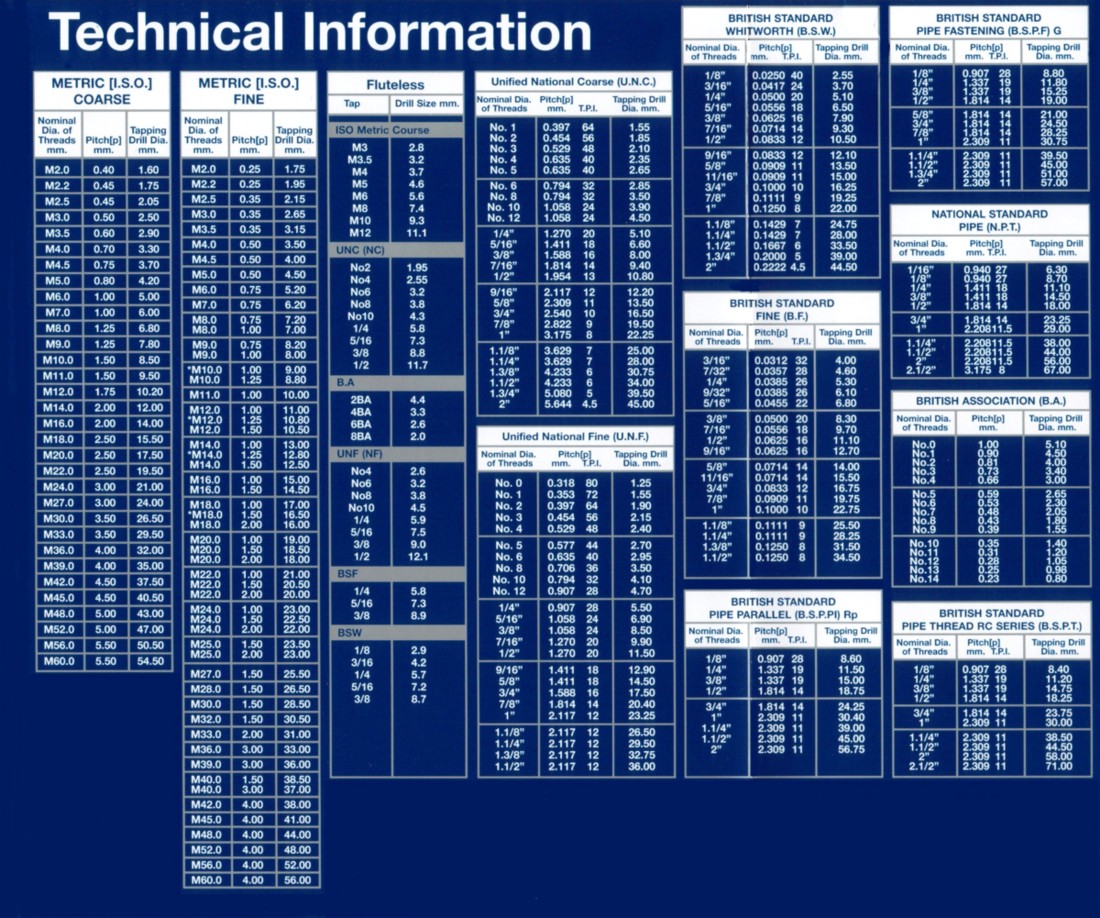

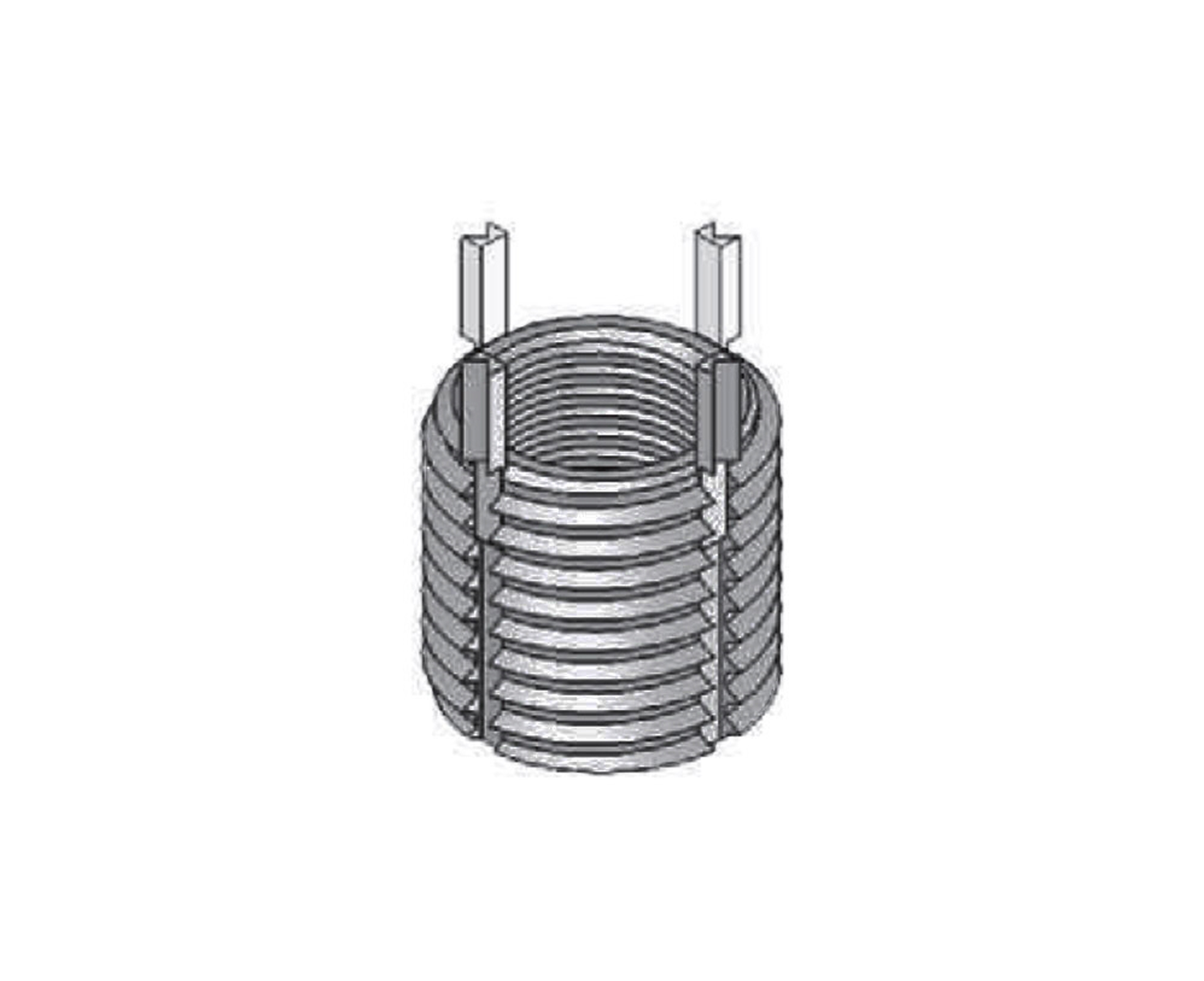

Keensert Drill Chart - Keenserts ® threaded inserts are the perfect solution to prevent threads from becoming stripped in fields like mechanical or precision engineering, aviation and aerospace. Buy online or request a quote today. Click here for more technical information. Keysert® and keensert® thread repair inserts the solid alternative for thread repair designed to repair damaged threads or for use in original equipment, keyserts® and keenserts®. The insert is provided with keys that lock the insert to the workpiece during. Designed to repair damaged threads or for use in original equipment, keyserts® and keenserts® provide easy installation and versatility. What is a solid insert? The keensert® locking thread repair keys provide a positive mechanical lock that prevents rotation due to vibration or torsion. Keenserts® are the perfect solution to prevent threads from becoming stripped in fields like mechanical or precision engineering, aviation and aerospace. Camloc keenserts ® are high strength solid inserts perfect for strengthening existing threads, or repairing or replacing damaged or stripped threads, enabling. Keysert® and keensert® thread repair inserts the solid alternative for thread repair designed to repair damaged threads or for use in original equipment, keyserts® and keenserts®. The keensert® locking thread repair keys provide a positive mechanical lock that prevents rotation due to vibration or torsion. Buy online or request a quote today. The insert is provided with keys that lock the insert to the workpiece during. Designed to repair damaged threads or for use in original equipment, keyserts® and keenserts® provide easy installation and versatility. Camloc keenserts ® are high strength solid inserts perfect for strengthening existing threads, or repairing or replacing damaged or stripped threads, enabling. What is a solid insert? Keensert® inserts are available in carbon or stainless steel,. Keenserts ® threaded inserts are the perfect solution to prevent threads from becoming stripped in fields like mechanical or precision engineering, aviation and aerospace. Keenserts® are the perfect solution to prevent threads from becoming stripped in fields like mechanical or precision engineering, aviation and aerospace. They are highly advantageous for replacing damaged or stripped threads,. What is a solid insert? Keysert® and keensert® thread repair inserts the solid alternative for thread repair designed to repair damaged threads or for use in original equipment, keyserts® and keenserts®. Camloc keenserts ® are high strength solid inserts perfect for strengthening existing threads, or repairing or replacing damaged or. What is a solid insert? Click here for more technical information. Designed to repair damaged threads or for use in original equipment, keyserts® and keenserts® provide easy installation and versatility. Keysert® and keensert® thread repair inserts the solid alternative for thread repair designed to repair damaged threads or for use in original equipment, keyserts® and keenserts®. Keenserts ® threaded inserts. Keensert® inserts are available in carbon or stainless steel,. Keenserts® are the perfect solution to prevent threads from becoming stripped in fields like mechanical or precision engineering, aviation and aerospace. What is a solid insert? Designed to repair damaged threads or for use in original equipment, keyserts® and keenserts® provide easy installation and versatility. Click here for more technical information. What is a solid insert? Designed to repair damaged threads or for use in original equipment, keyserts® and keenserts® provide easy installation and versatility. The keensert® locking thread repair keys provide a positive mechanical lock that prevents rotation due to vibration or torsion. Camloc keenserts ® are high strength solid inserts perfect for strengthening existing threads, or repairing or replacing. The insert is provided with keys that lock the insert to the workpiece during. Designed to repair damaged threads or for use in original equipment, keyserts® and keenserts® provide easy installation and versatility. Camloc keenserts ® are high strength solid inserts perfect for strengthening existing threads, or repairing or replacing damaged or stripped threads, enabling. What is a solid insert?. Keenserts ® threaded inserts are the perfect solution to prevent threads from becoming stripped in fields like mechanical or precision engineering, aviation and aerospace. They are highly advantageous for replacing damaged or stripped threads,. The insert is provided with keys that lock the insert to the workpiece during. The keensert® locking thread repair keys provide a positive mechanical lock that. The keensert® locking thread repair keys provide a positive mechanical lock that prevents rotation due to vibration or torsion. Designed to repair damaged threads or for use in original equipment, keyserts® and keenserts® provide easy installation and versatility. Keenserts® are the perfect solution to prevent threads from becoming stripped in fields like mechanical or precision engineering, aviation and aerospace. Buy. Camloc keenserts ® are high strength solid inserts perfect for strengthening existing threads, or repairing or replacing damaged or stripped threads, enabling. Keensert® inserts are available in carbon or stainless steel,. Keenserts ® threaded inserts are the perfect solution to prevent threads from becoming stripped in fields like mechanical or precision engineering, aviation and aerospace. The insert is provided with. They are highly advantageous for replacing damaged or stripped threads,. Designed to repair damaged threads or for use in original equipment, keyserts® and keenserts® provide easy installation and versatility. The insert is provided with keys that lock the insert to the workpiece during. Keysert® and keensert® thread repair inserts the solid alternative for thread repair designed to repair damaged threads. Keenserts ® threaded inserts are the perfect solution to prevent threads from becoming stripped in fields like mechanical or precision engineering, aviation and aerospace. What is a solid insert? Camloc keenserts ® are high strength solid inserts perfect for strengthening existing threads, or repairing or replacing damaged or stripped threads, enabling. Keensert® inserts are available in carbon or stainless steel,.. Keenserts ® threaded inserts are the perfect solution to prevent threads from becoming stripped in fields like mechanical or precision engineering, aviation and aerospace. Designed to repair damaged threads or for use in original equipment, keyserts® and keenserts® provide easy installation and versatility. Keysert® and keensert® thread repair inserts the solid alternative for thread repair designed to repair damaged threads or for use in original equipment, keyserts® and keenserts®. Keensert® inserts are available in carbon or stainless steel,. Keenserts® are the perfect solution to prevent threads from becoming stripped in fields like mechanical or precision engineering, aviation and aerospace. Camloc keenserts ® are high strength solid inserts perfect for strengthening existing threads, or repairing or replacing damaged or stripped threads, enabling. Buy online or request a quote today. What is a solid insert? The keensert® locking thread repair keys provide a positive mechanical lock that prevents rotation due to vibration or torsion.Tap Drill Size Chart For Standard Threads In Mm at Patrick Bautista blog

Metric Keensert Tap Drill Chart at Reginald Heilig blog

Keensert tap drill chart booystatus

Keensert Guide Screw Metalworking

Keensert Drill And Tap Chart Ponasa

Stabil drill z bit windows, used tools for sale victoria bc, keensert drill chart metric weight

Stabil drill z bit windows, used tools for sale victoria bc, keensert drill chart metric weight

Keensert Removal Drill Size at Sara Long blog

Metric Keensert Tap Drill Chart at Reginald Heilig blog

Keensert Drill And Tap Chart Ponasa

Click Here For More Technical Information.

They Are Highly Advantageous For Replacing Damaged Or Stripped Threads,.

The Insert Is Provided With Keys That Lock The Insert To The Workpiece During.

Related Post: