Calibration Chart Chart Industries

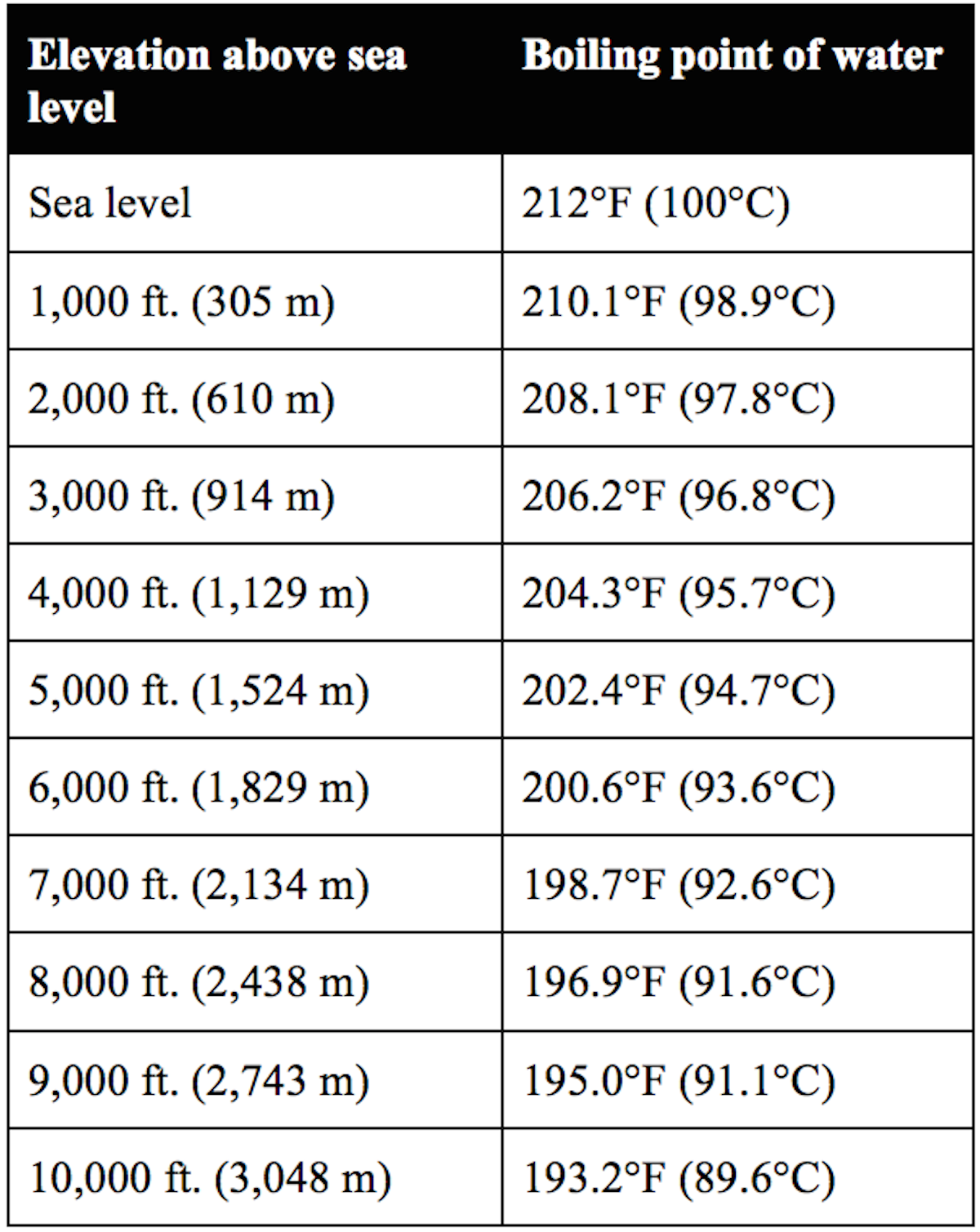

Calibration Chart Chart Industries - Calibration is the act of comparing a device under test (dut) of an unknown value with a reference standard of a known value. Learn about the meaning of calibration, calibration uncertainty, traceability, why and how often to calibrate and how to calibrate. Calibration is the process of adjusting and verifying the accuracy of a measuring instrument or system, such as an electronic device or sensor, to ensure that it provides the. The process of comparison of a device with unknown accuracy to a device with a known, accurate standard to eliminate any variation in the device being checked is called calibration. Learn how it mitigates risks, reduces costs, and ensures compliance. A person typically performs a calibration to determine. Calibration is the process of comparing the readings of a measuring instrument with a known standard value and making adjustments if needed. Discover the critical role of calibration in industrial manufacturing. It ensures that the instrument. To calibrate testing equipment is to level gear so measurements remain accurate and consistent. The process of comparison of a device with unknown accuracy to a device with a known, accurate standard to eliminate any variation in the device being checked is called calibration. Calibration is the act of comparing a device under test (dut) of an unknown value with a reference standard of a known value. Learn how it mitigates risks, reduces costs, and ensures compliance. A person typically performs a calibration to determine. To calibrate testing equipment is to level gear so measurements remain accurate and consistent. Learn about the meaning of calibration, calibration uncertainty, traceability, why and how often to calibrate and how to calibrate. Calibration is the process of comparing the readings of a measuring instrument with a known standard value and making adjustments if needed. Calibration is the process of adjusting and verifying the accuracy of a measuring instrument or system, such as an electronic device or sensor, to ensure that it provides the. At its core, calibration is the process of comparing the performance of a measurement device (such as a thermometer, scale, or pressure gauge) against a recognized. In measurement technology and metrology, calibration is the comparison of measurement values delivered by a device under test with those of a calibration standard of known accuracy. Calibration is the act of comparing a device under test (dut) of an unknown value with a reference standard of a known value. Learn about the meaning of calibration, calibration uncertainty, traceability, why and how often to calibrate and how to calibrate. The process of comparison of a device with unknown accuracy to a device with a known, accurate standard. To calibrate testing equipment is to level gear so measurements remain accurate and consistent. Learn how it mitigates risks, reduces costs, and ensures compliance. In measurement technology and metrology, calibration is the comparison of measurement values delivered by a device under test with those of a calibration standard of known accuracy. Learn about the meaning of calibration, calibration uncertainty, traceability,. It ensures that the instrument. Discover the critical role of calibration in industrial manufacturing. Calibration is the process of adjusting and verifying the accuracy of a measuring instrument or system, such as an electronic device or sensor, to ensure that it provides the. Learn about the meaning of calibration, calibration uncertainty, traceability, why and how often to calibrate and how. Discover the critical role of calibration in industrial manufacturing. At its core, calibration is the process of comparing the performance of a measurement device (such as a thermometer, scale, or pressure gauge) against a recognized. To calibrate testing equipment is to level gear so measurements remain accurate and consistent. Calibration is the process of adjusting and verifying the accuracy of. It ensures that the instrument. The process of comparison of a device with unknown accuracy to a device with a known, accurate standard to eliminate any variation in the device being checked is called calibration. In measurement technology and metrology, calibration is the comparison of measurement values delivered by a device under test with those of a calibration standard of. Calibration is the process of comparing the readings of a measuring instrument with a known standard value and making adjustments if needed. Learn about the meaning of calibration, calibration uncertainty, traceability, why and how often to calibrate and how to calibrate. To calibrate testing equipment is to level gear so measurements remain accurate and consistent. Learn how it mitigates risks,. At its core, calibration is the process of comparing the performance of a measurement device (such as a thermometer, scale, or pressure gauge) against a recognized. To calibrate testing equipment is to level gear so measurements remain accurate and consistent. A person typically performs a calibration to determine. Discover the critical role of calibration in industrial manufacturing. Learn about the. A person typically performs a calibration to determine. At its core, calibration is the process of comparing the performance of a measurement device (such as a thermometer, scale, or pressure gauge) against a recognized. Calibration is the process of adjusting and verifying the accuracy of a measuring instrument or system, such as an electronic device or sensor, to ensure that. To calibrate testing equipment is to level gear so measurements remain accurate and consistent. Calibration keeps results honest and trustworthy, which counts In measurement technology and metrology, calibration is the comparison of measurement values delivered by a device under test with those of a calibration standard of known accuracy. Discover the critical role of calibration in industrial manufacturing. Calibration is. Learn how it mitigates risks, reduces costs, and ensures compliance. The process of comparison of a device with unknown accuracy to a device with a known, accurate standard to eliminate any variation in the device being checked is called calibration. Learn about the meaning of calibration, calibration uncertainty, traceability, why and how often to calibrate and how to calibrate. At. Calibration is the process of comparing the readings of a measuring instrument with a known standard value and making adjustments if needed. In measurement technology and metrology, calibration is the comparison of measurement values delivered by a device under test with those of a calibration standard of known accuracy. Discover the critical role of calibration in industrial manufacturing. Calibration is the process of adjusting and verifying the accuracy of a measuring instrument or system, such as an electronic device or sensor, to ensure that it provides the. Calibration is the act of comparing a device under test (dut) of an unknown value with a reference standard of a known value. The process of comparison of a device with unknown accuracy to a device with a known, accurate standard to eliminate any variation in the device being checked is called calibration. Calibration keeps results honest and trustworthy, which counts A person typically performs a calibration to determine. At its core, calibration is the process of comparing the performance of a measurement device (such as a thermometer, scale, or pressure gauge) against a recognized. Learn how it mitigates risks, reduces costs, and ensures compliance.How to Calibrate a Thermometer Craft Beer & Brewing Magazine

Calibration Traceability Chart A Visual Reference of Charts Chart Master

Calibration Chart Calibration Chart Calibration Chart Calibration Chart PDF

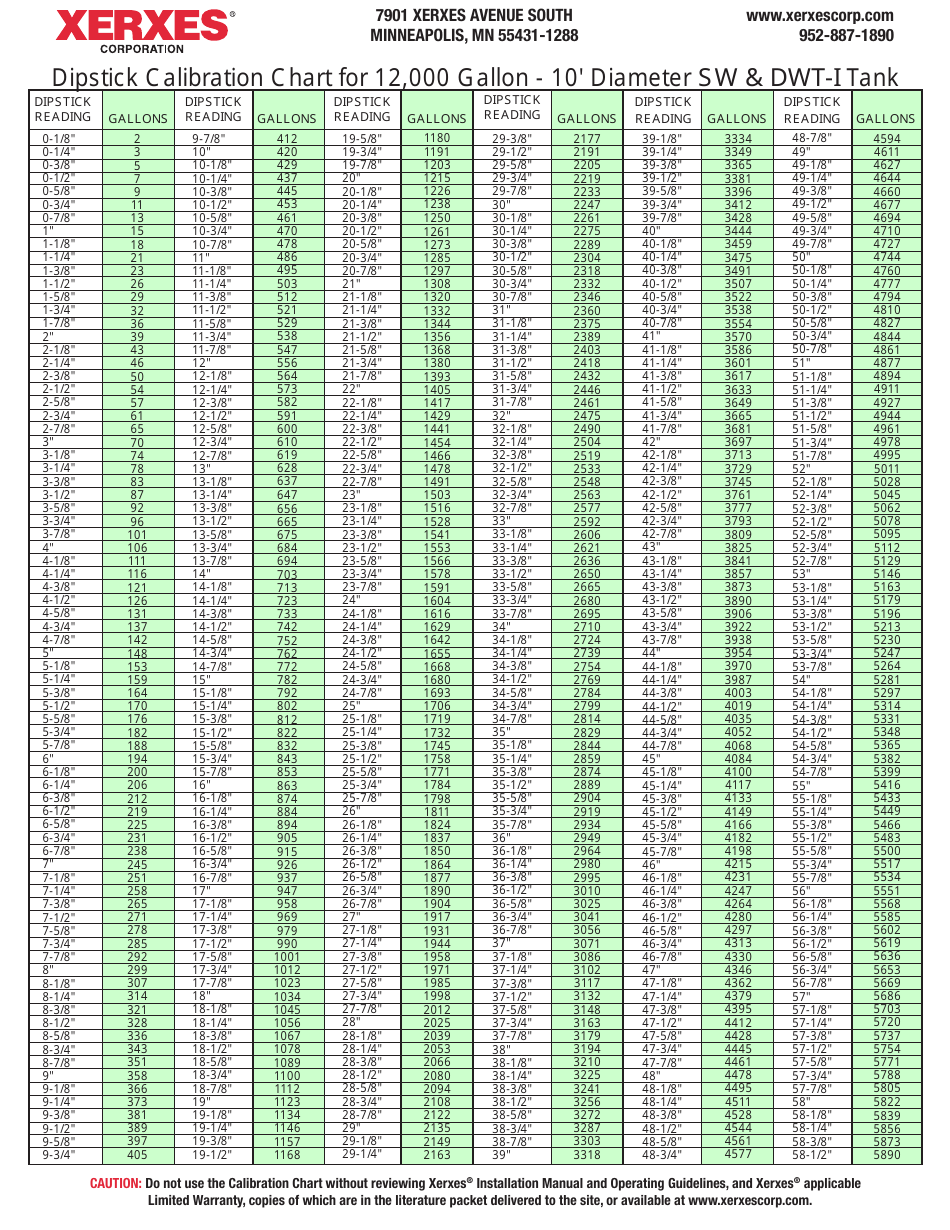

Dipstick Calibration Chart Xerxes Corporation Download Printable PDF Templateroller

Calibration charts. (A, B) Calibration chart of 2‐year cumulative CVD... Download Scientific

Scale Calibration Log Sheet

THE CALIBRATION FLOW CHART

Tank Calibration Charts AfrisoEurogauge

Calibration Chart Format PDF Nature

Calibration chart. Download Scientific Diagram

It Ensures That The Instrument.

Learn About The Meaning Of Calibration, Calibration Uncertainty, Traceability, Why And How Often To Calibrate And How To Calibrate.

To Calibrate Testing Equipment Is To Level Gear So Measurements Remain Accurate And Consistent.

Related Post: